5 Best Digital Textile Printing Technologies: Inks, Processes & Sustainable Practices

Table of Contents

Digital textile printing technologies has been gaining importance for years, with technological progress enabling faster, more precise printing and – most importantly – reduced environmental impact. The choice of technology depends on the type of fabric, desired color effects, print durability, as well as process and environmental requirements.

Below, we discuss five main digital textile printing technologies: reactive, acid, pigment, disperse direct, and sublimation, outlining their characteristics, inks used, required processes, pre-treatment needs, and their impact on energy and water consumption.

Digital Textile Printing Technologies: Acid Printing Technology

Acid printing technology uses acid dyes to produce deep, brilliant colors on protein-based fibers such as silk, wool, and nylon. The process involves steaming and thorough washing to fix the colors, resulting in high water and energy consumption but unmatched vibrancy and softness for luxury textiles.

Characteristics and Ink

Acid inks are intended for protein fibers (wool, silk) and polyamide/nylon. The dye binds ionically with the fiber, producing extremely vivid colors, high wash fastness, and excellent UV resistance. Neon colors are also possible.

Pre-Treatment Requirement

Essential. Preparation baths enhance ink penetration, regulate droplet spread, and incorporate pH buffers to maintain optimal dye–fiber interaction.

Energy & Water Usage

- Energy: high (steam + baths).

- Water: 40–60 L/m².

Production Process of Acid Printing

Digital Textile Printing Technologies: Reactive Printing Technology

Reactive printing technology uses reactive dyes that form a strong chemical bond with natural fibers such as cotton, linen, and silk. This method delivers vibrant colors with excellent wash and lightfastness, making it ideal for high-quality apparel and home textiles. It requires pre-treatment and post-print washing, resulting in higher water usage but superior durability.

Characteristics and Ink

This technology uses water-based reactive inks that form permanent covalent bonds with cellulosic fibers (cotton, viscose, linen) and some protein fibers (e.g., silk). The result is intense, saturated colors, deep blacks, and high wash fastness.

Pre-Treatment Requirement

Pre-treatment is essential in reactive printing. Fabrics are coated with a solution containing alkaline agents, thickeners, and salts to create permanent bonds between dye and fiber. Skipping this step significantly reduces color saturation and compromises print durability.

Energy & Water Usage

- Energy: highest among digital technologies (steam + multiple washes)

- Water: 50–70 L/m²

Production Process of Reactive Printing

Digital Textile Printing Technologies: Pigment Printing Technology

Pigment printing technology applies pigment-based inks directly to the fabric surface, bonding them with a binder during heat fixation. This process works on a wide range of fiber types and is valued for its low water consumption and simplified workflow. It is especially suitable for short runs, sampling, and sustainable production through single-step systems.

Characteristics and Ink

Pigment inks remain on the fiber surface and are fixed thermally or with IR. They can be used on most fibers without changing the ink set. Colors are stable, UV-resistant, and modern pigment formulations can achieve high saturation. Neon color options are also available.

Pre-Treatment Requirement

Traditionally recommended for maximum quality and durability. However, modern “single-step” systems integrate substrate preparation and fixation in one pass, eliminating the need for pre-treatment and removing wet processing entirely.

Energy & Water Usage

• Energy: lowest among mass-production digital technologies (no steam, short thermal cycle).

• Water: 0–2 L/m² (often <1 L/m² in “single-step” systems).

Production Process of Acid Printing

Single-Step Machines for Pigment Printing

Atexco Vega X1 Pro

4/6/8 Colors

16 Kyocera Printheads

Up to 480 m²/h Speed

1,800mm max printing width

The Vega X1 Pro in its single-step configuration combines fabric preparation, printing, and fixation in one process. The inline pre-treatment system applies the necessary coating as the fabric feeds through, so there’s no need for separate pre-treat or wet processing stages. This reduces handling, shortens production time, and cuts water use. It can work with different fabrics and ink types in a continuous pass, making the workflow simpler and more efficient while maintaining print quality.

Digital Textile Printing Technologies: Disperse Direct Printing

Disperse printing technology uses disperse dyes that are sublimated into synthetic fibers like polyester under heat and pressure. The method offers excellent colorfastness and a soft fabric feel, often involving high-temperature steaming and washing stages. It’s ideal for sportswear, fashion, and interior textiles made from synthetic materials.

Characteristics and Ink

Disperse inks are designed for polyester; the dye diffuses into the fiber during thermo-fixation. They provide high wash fastness and good UV resistance.

Pre-Treatment Requirement

On disperse direct painting, pre-treatment is optional. Printing without it is common, though it may improve print uniformity and reduce dye migration in demanding applications.

Energy & Water Usage

• Energy: moderate–high (high-temp fixation + washing).

• Water: 15–30 L/m².

Production Process of Acid Printing

1- Pre-Treatment (optional)

2- High-Temperature Thermal Fixation

3- Cold Wash

4- Hot Wash

5- Sometimes Reduction Clearing for Fark Shades

6- Drying

Digital Textile Printing Technologies: Sublimation Printing (Dye-Sub)

Sublimation printing technology transfers designs from printed transfer paper to polyester fabrics using heat and pressure. The dyes turn into gas and bond with the fibers, producing vibrant, permanent prints with no added texture. This dry process requires no post-print washing, making it efficient and environmentally friendly.

Characteristics and Ink

The most popular method for polyester and polyester-coated materials. Printing is done on transfer paper, and then the design is transferred onto the fabric at high temperature.

Pre-Treatment Requirement

On dye sublimation printing method, pre-treatment is not required. The dye transfer process from paper to fabric at high temperature does not need prior substrate preparation.

Energy & Water Usage

• Energy: low–moderate (heat transfer as the main stage).

• Water: 0–1 L/m² (mainly from cleaning, cooling, or air humidification).

Production Process of Acid Printing

Dye sublimation printing involves transferring the printed design onto the fabric using heat and pressure in a calender or heat press. The process requires no post-print washing, making it clean and efficient.

Exceptional Dye Sublimation Printers

Atexco Model H Hs

4 Colors (CMYK)

16 Kyocera Printheads

Up to 1360 m²/h Speed

1,800mm max printing width

The Atexco Model H HS is designed for maximum production speed, making it the fastest dye sublimation printer on the market. Built for high-volume textile workflows, it delivers exceptional throughput without compromising print quality, meeting the demands of large-scale, time-critical orders.

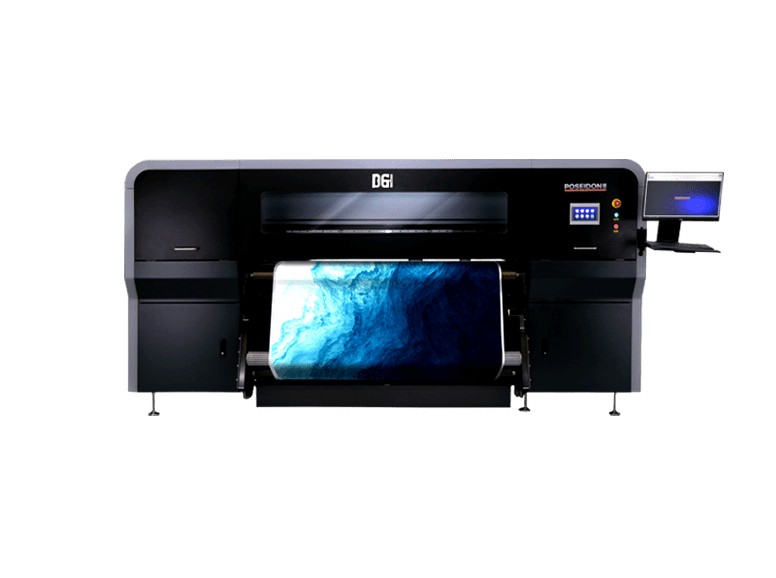

DGI-d.gen Poseidon II

4 Colour (2-Staggers), Up to 760m/h Speed

Max Printing Width 1,820mm

The Poseidon II can print using either 4 or 8 colors, driven by 4 or 8 Kyocera heads. It handles media up to 1,820 mm wide and delivers impressive production speeds—peaking around 760 m²/hr at lower dpi, or holding excellent quality up to 1,800 dpi at slightly slower yet still industrial rates.

Energy and water consumption comparison table

| Technology | Energy Consumption | Water Usage (L/m²) | Water-Related Notes |

|---|---|---|---|

| Pigment | Lowest – no steam, short thermal cycle | 0–2 | Water only for cleaning and auxiliary processes; in “single–step” often <1 L/m² |

| Sublimation | Low–moderate – heat transfer | 0–1 | No wet processing; usage mainly from cleaning, cooling, or air humidification |

| Disperse direct | Moderate–high – high temp + washing | 15–30 | Cold/warm washes and sometimes reduction clearing |

| Acid | High – steam + baths | 40–60 | Cold and warm washes, wet processing required |

| Reactive | Highest – steam + multi-stage washes | 50–70 | Multiple cold and hot washes, high water intensity |

Comparison of Digital Textile Printing Technologies

| Technology | Mechanism of Action | Substrates | Direct/Transfer | Wash Fastness | UV Resistance | Color Saturation | Neon Colors | Required Post-Printing Processes | Advantages | Limitations |

|---|---|---|---|---|---|---|---|---|---|---|

| Reactive | Covalent bonding with cellulose after steaming | Cotton, viscose, linen, silk | Direct | Very high | Medium–good | Very high | Not available | Steaming (100–105 °C, 12–15 min) → cold rinse → hot wash/soaping (80–95 °C) or repeated cold rinse (dark shades) → drying | Top wash fastness, deep colors | Complex wet processing, high water use |

| Acid | Bonding with protein fibers and nylon after steaming | Silk, wool, nylon | Direct | High | High | Very high | Available | Steaming (102–105 °C, 20–40 min) → hot wash → warm wash (40–60 °C) → cold rinse (often repeated) → drying | Very vivid colors, high durability | Limited substrates, thermal sensitivity |

| Pigment | Pigment in a binder on surface; curing | Most natural & synthetic fibers | Direct | Medium–high | Very high | Medium–high | Available | Thermal curing/IR (150–170 °C) → no post-washing | Universal, low water use | Durability depends on binder chemistry, lower softness |

| Disperse Direct | Disperse dye penetrates PES; thermofixation | Polyester | Direct/Transfer | High | Medium–high | High | Available | Thermofixation (180–210 °C) → cold rinse → hot wash/soaping (90 °C) → reduction clearing (65–70 °C) → cold rinse | Good durability, deep saturation | High temperature, reduction clearing required |

| Sublimation (Dye-Sub) | Transfer from paper; dye sublimates into PES | Polyester, coated PES | Transfer | High | Low–medium | High | Available | Heat press or calender (180–205 °C) → no post-washing | Simplest process, fast turnaround | Only PES/coatings, poor UV resistance |

Ecological aspect and future of pigment printing

Pigment digital printing, thanks to the absence of wet processes, is the technology with the greatest potential in low-emission and water-saving strategies for the textile industry. Advances in ink formulations enable:

- achieving saturation levels comparable to reactive printing,

- improving wash fastness,

- printing on multiple fabric types in a single process,

- reducing or eliminating pre-treatment.

In the context of global environmental regulations and increasing consumer pressure, process-shortening, water- and energy-minimizing technologies – such as pigment – will become the backbone of digital textile production.

Ready to make your textile production faster, cleaner, and more sustainable?

Discover how the right printing technology can reduce water, energy, and waste without sacrificing quality.